CNC End Mills For Cutting R/C Plane Parts - MARCH 2020

My R/C plane parts are cut from 6,3 and 1.5mm ply. I also cut wing ribs from 1.5 and 3mm Balsa and occasionally cut 6mm foam board.

For cutting accuracy and cutting slots and complex shapes I use 1.0 mm downcut End Mills.

Typical feed rates I use on my CNC Router are 400 to 600 mm/minute. The highest speed is used with foam board.

It's very important to ensure that the bed is level otherwise when cutting thin materials the part may not be completely cut out.

I milled an MDF board that is fixed on top of the bed using a 1/4 inch tungsten carbide cutter to ensure that I had a surface that was perpendicular to the cutter.

A 3mm ply spoil board is attached to this board with 1/4 inch bolts with flat heads.

The End Mills I use were purchased from www.precisebits.com. They are reasonably priced, high quality, durable, and create a very nice clean cut.

1.0mm Downcut 2 Flute Fish-Tail End Mill Part No. MD208-0394-013F

These End Mills have a 1/8 shaft diameter so I use a reducing collet adapter that goes from 1/4 inch to 1/8 inch. This works fine in my Ryobi Plunge Router with a 1/4 inch chuck.

To get push fits when creating parts that slot together I use Inside Offset cuts for holes and Outside Offset cuts for part outlines.

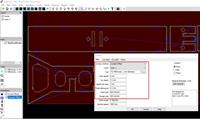

The SheetCam pictures are for undercarriage parts for a tricycle undercarriage mod for the RCPowers F22.

The pictures are shown below.

No Comments

Date Posted: 10/03/2020 10:00:00 PM

Winfoil 3 Other Details

User Portal

Articles

- 2FA

- 3.0.49

- 3.0.51

- 3.0.52

- 3.0.53

- 3D Printing

- 3D Printing for RC Aircraft

- About

- Activation Enhancement

- Airfoil List Screen Enhancement

- Airfoil List Screen Enhancements 2

- Airfoil Plotter

- Airfoil Plotting

- Airfoils

- Airfoils not showing after import

- April 2020

- APRIL 2021

- August 2020

- CNC

- CNC Router

- Creality

- Decals

- Default Length Units

- Design Specification

- Download Winfoil

- DXF Export Enhancement

- End Mills

- Ender 3 Pro

- FEBRUARY 2021

- Issue

- JANUARY 2024

- Jig Hole Washout

- July 2020

- June 2020

- Lost Password Link Issue

- March 2020

- MARCH 2024

- MAY 2020

- October 2020

- Print Orientation Issue

- Roadmap

- Show Password

- Two-factor Authentication

- V3.0.45

- V3.0.52

- V3.0.53 APRIL 2021

- V3.0.55

- V3.0.56

- V3.0.57

- Version History

- Washout

- Weight and Balance

- Winfoil V3.0.51

- Winfoil V3.0.52 MARCH 2021

- Wing Plan View